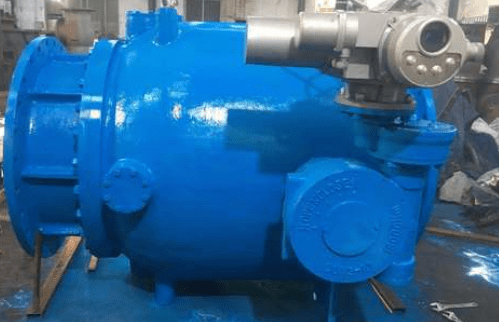

Plunger Valve

Plunger Valve Supplier in Dubai, UAE Valves delivers engineered control valves designed for safe and stable flow regulation across high pressure drops. Also called plunger control valves or anti-cavitation valves, these energy-dissipating valves use a guided plunger and sleeve or cage to stage pressure loss. By managing cavitation inside the trim, they protect downstream assets, reduce noise and vibration, and ensure reliable operation in desalination, hydropower, district cooling, and power generation networks.

How Plunger Valves Work

A plunger valve regulates flow by moving a plunger axially toward a shaped seat or a multi-hole sleeve. As the plunger closes, fluid passes through staged ports that break pressure gradually, collapsing vapor bubbles before they can erode the pipeline. This results in smooth throttling, dependable sealing at shutoff, and longer service life.

Plunger valves can be operated manually or automated with electric, pneumatic, or hydraulic actuators, and can integrate position feedback for plant control systems.

Benefits of Plunger Valves

- Cavitation-free throttling at high differential pressures

- Low vibration and noise through multi-stage energy dissipation

- Tight shutoff with guided trim and protected sealing areas

- Long service life with replaceable sleeves and hardfaced wear surfaces

- Top-entry maintenance design that reduces downtime during service

Technical Specifications

- Size range: DN 80 – DN 2000 (3″–80″)

- Pressure ratings: PN 10 – PN 40; ASME Class 150 on request

- Temperature range: 0 °C to 120 °C for water service; higher with special alloys

- End connections: flanged RF to EN or ASME standards; hubs available on request

- Face-to-face: EN 558 series; custom retrofit lengths available

- Coatings: fusion bonded epoxy or epoxy phenolic for seawater and buried service

- Control characteristics: near-linear with stable rangeability

- Actuation: manual gearbox, electric, pneumatic, or hydraulic with positioner

Design Standards

- ASME B16.34 – design and pressure-temperature ratings

- IEC 60534 – control valve sizing and performance

- EN 1074 – valves for water supply systems

- ISO 5211 – actuator mounting interface

- NSF or equivalent – potable water approvals where required

Inspection and Testing

- Hydrostatic shell and seat testing to ISO 5208 / API 598

- Functional stroke tests with travel and thrust verification

- Coating inspection and holiday testing to AWWA C550

- Noise and cavitation evaluation to IEC 60534 when required

- Full material traceability to EN 10204 3.1 or 3.2 with certification packs

Body & Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Ductile Iron | EN-GJS-450-10 + epoxy lining | EN 1563 / AWWA refs | Potable water, distribution |

| Cast Carbon Steel | WCB, WCC | ASTM A216 | Cooling water, industrial lines |

| Cast Stainless Steel | CF8M (316), CF3M | ASTM A351 | Brackish water, RO, corrosive service |

| Forged Stainless | F316, F316L | ASTM A182 | High pressure trims and stems |

| Duplex / Super Duplex | F51 (2205), F55 (2507) | ASTM A182 / A890 | Seawater, chloride-rich service |

| Bronze / Aluminium Bronze | C83600, C95800 | ASTM B148 | Marine service, splash zones |

| Nickel Alloys | Inconel 625, Monel 400 | ASTM B564 | Severe corrosion, erosion duty |

Industries Served

- Water and Desalination: reservoir outlets, RO bypass, distribution mains

- Hydropower: turbine bypass, bottom outlets, level control

- District Cooling: pump discharge regulation and branch balancing in chilled water networks

- Power Generation: condenser cooling, auxiliary systems, blowdown control

- Petrochemical & Chemical: process utilities and clean fluid regulation under high differential pressure

- Oil & Gas: utility water, treated water, and injection lines

- Marine & Offshore: cooling water, ballast, and firewater duties

- Mining & Metals: reagent dosing, slurry side streams, and plant water circuits

- Industrial Utilities: compressed air, cooling water, general service lines

Special Features

- Multi-stage anti-cavitation sleeves that dissipate energy within the trim

- Replaceable cartridge trims for quick turnaround during planned outages

- Bypass and vacuum breaker ports for transient protection during startup/shutdown

- Travel stops and stroke limiters to define safe operating ranges

- Position transmitters for diagnostics and remote monitoring

- Stem extensions and buried service kits for underground installations

- Customization for trim geometry, actuator type, coating systems, and face-to-face dimensions

Showing the single result