Ball Valve Supplier in Dubai — Isolation and Flow Control for Every Application

Ball valves are quarter-turn shut-off valves designed to start, stop, and regulate flow using a rotating spherical disc. The valve opens when the port in the ball aligns with the pipeline and closes when the ball is turned 90 degrees. Their simple mechanism, compact construction, and minimal pressure drop make ball valves widely used across oil & gas, chemical plants, power stations, water treatment systems, marine operations, and general industrial process applications.

What Is a Ball Valve?

A ball valve is a mechanical device consisting of a metal or alloy body, a floating or trunnion-mounted ball, PTFE/metallic seats, stem, and end connections. It allows quick isolation through a quarter-turn rotation. Ball valves offer full-bore or reduced-bore options, low torque operation, and compatibility with manual, pneumatic, electric, and hydraulic actuators.

How Ball Valves Work?

1)The ball has a central passage (port).

2)When the handle or actuator rotates the ball by 90°, the port aligns with the flow path, allowing fluid to pass.

3)Turning the ball again blocks the passage, creating shut-off.

4)Seats positioned around the ball ensure tight sealing.

5)Trunnion-mounted designs use fixed bearings for higher pressure applications.

This straightforward mechanism allows consistent operation in gases, liquids, steam, and abrasive media, depending on material selection.

Ball Valve Benefits:

1)Quarter-turn operation for fast opening and closing

2)Minimal pressure drop across the valve

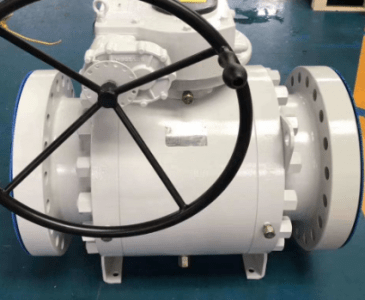

3)Suitable for automation (ISO 5211 mounting pad)

4)Tight sealing performance

5)Adaptable to high-pressure and high-temperature conditions

6)Wide choice of body, seat, and trim materials

7)Applicable to clean, corrosive, and erosive fluids depending on configuration

Types of Ball Valves We Supply

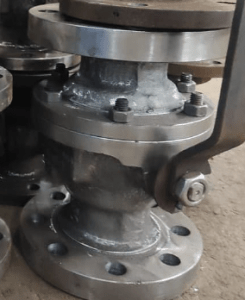

1)Floating Ball Valve

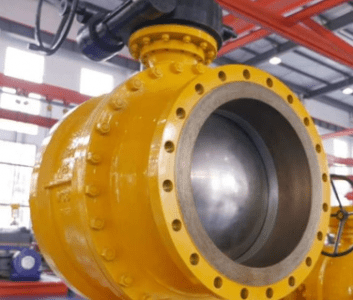

2)Trunnion-Mounted Ball Valve

3)Double Block & Bleed (DBB) Ball Valve

4)Welded Body Ball Valve

5)Top Entry Ball Valve

6)Jacketed Ball Valve

Ball valves are widely used in:

1)Oil & Gas (onshore / offshore)

2)Petrochemical and chemical plants

3)Water distribution, desalination, and wastewater systems

4)Power generation

5)Marine and shipbuilding

6)Mining and slurry handling

7)Fire protection and utility services

Technical Specifications

- Size range: DN 15 to DN 1200 (½ in to 48 in), service dependent

- Pressure ratings: ASME Class 150 to 2500; PN 10 to PN 420

- Temperature range: −196 °C to +600 °C (material and seat dependent)

- Bore options: full bore and reduced bore

- End connections: flanged RF or RTJ, butt weld, socket weld, threaded for small sizes; hubs on request

- Face to face: ASME B16.10 and EN 558 series

- Seats: PTFE, RPTFE, filled PTFE, PEEK, Devlon, and metal seated (HVOF or Stellite) for severe service

- Features: antistatic device, blowout proof stem, cavity pressure relief, ISO 5211 actuator pad

Design Standards

- API 6D for pipeline and trunnion ball valves

- ISO 17292 and API 608 for industrial ball valves

- ASME B16.34 for design and pressure temperature ratings

- ASME B16.5 and B16.47 for flanges; ASME B16.10 for face to face dimensions

- Fire safe qualification to API 607 or API 6FA when specified

Inspection and Testing

- API 598 and ISO 5208 pressure and leakage tests for industrial valves

- API 6D factory acceptance tests for trunnion and pipeline valves, including hydrostatic shell and seat and low pressure gas seat

- Fugitive emission testing to ISO 15848 on request

- Helium leak testing for critical services when specified

- NDE per project requirement (MPI, UT, RT) and positive material identification where required

As a manufacturer, we record seat leakage classes and torque curves and supply EN 10204 3.1 or 3.2 certification packs.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Cast Carbon Steel | WCB, WCC | ASTM A216 | Hydrocarbons, steam, general service |

| Low Temperature Carbon Steel | LCB, LCC | ASTM A352 | Low temperature utility and process lines |

| Forged Carbon Steel | A105, LF2 | ASTM A105 / A350 | High pressure small bore and topsides |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, water, chemicals |

| Forged Stainless | F304/L, F316/L | ASTM A182 | Trims, stems, and high pressure bodies |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / A890 | Seawater, RO and desalination, chlorides |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / A351 | High chloride service, desalination |

| Nickel Alloys | Monel 400, Inconel 625 / 718 | ASTM B564 | Sour gas, aggressive media, high temperature |

| Hastelloy | C276, B3 | ASTM B574 / B564 | Oxidizing and halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid duty |

| Cast Iron | Class B, EN-GJL-250 | ASTM A126 Cl B / EN-GJL-250 | Water and utility duties |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and seawater systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702 | ASTM B348 / B493 | Chlorides, seawater, specialty acids |

Showing 1–20 of 27 results