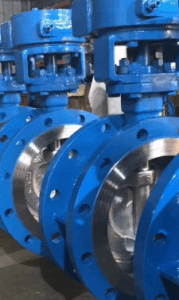

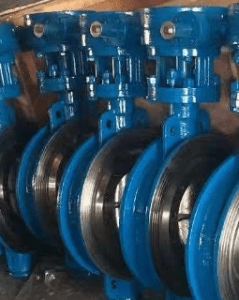

Butterfly Valve

As a Butterfly Valve Supplier in Dubai, UAE Valves provides quarter turn valves that use a rotating disc to start, stop, or throttle flow with a small footprint and low weight. The disc sits on a shaft inside the body; turn it in line with the flow for minimal loss, or turn it across the flow for shutoff. These valves are popular where fast operation, easy automation, and simple maintenance matter. Available in concentric, double offset, and triple offset designs, they cover utility duty through severe service with resilient or metal seats matched to temperature and pressure needs.

How Butterfly Valves Work

A circular disc turns ninety degrees on a shaft. Concentric designs seal on a resilient seat around the disc edge. Double offset moves the shaft and disc off center to cut friction and operating torque. Triple offset adds a conical seat and a metal seal ring for dependable tight sealing at higher temperatures and pressures.

Butterfly Valve Benefits

- Compact and light, so supports and space requirements stay low

- Low operating torque for easy manual, electric, or pneumatic actuation

- Tight shutoff with resilient seats; reliable performance with metal seats in demanding service

- Multiple face to face series and end connections for quick retrofit

- Quarter turn motion that is quick to operate and simple to interlock

Types of Butterfly Valves

- Concentric Butterfly Valve — resilient seated for general isolation and throttling

- Double Eccentric Butterfly Valve — offset geometry lowers wear and required torque

- Double Flanged Butterfly Valve — rigid flanged body for large diameters and critical lines

- Lug Butterfly Valve — allows downstream removal and mid line alignment

- Triple Eccentric Butterfly Valve — metal to metal sealing for high temperature or severe service

- Wafer Butterfly Valve — slim body for tight spaces and reduced weight

Technical Specifications

- Size range: DN 50 to DN 3000

- Pressure ratings: PN 10 to PN 40 for resilient seated; ASME Class 150 to 600 for high performance and triple offset

- Temperature range: −40 °C to +600 °C depending on body, disc, and seat materials

- End connections: wafer, lug, double flanged RF or RTJ; butt weld on selected triple offset designs

- Face to face: ISO 5752 and EN 558 series; API 609 tables

- Mounting: ISO 5211 topworks for direct actuator mounting

- Control characteristics: equal percentage or modified linear for throttling

Design Standards

- API 609 Category A and Category B

- EN 593 industrial butterfly valves

- ASME B16.34 design and pressure temperature ratings

- ASME B16.5 and B16.47 flanges; ISO 5752 and EN 558 face to face

Inspection and Testing

- API 598 and ISO 5208 pressure and leakage testing

- EN 12266 tightness verification

- Fire safe testing to API 607 for triple offset when specified

- Shaft blowout proof checks and torque testing performed in house

As a manufacturer, we log test data for each assembly and provide traceable certificates.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Hydrocarbons, steam, general service |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, brackish water |

| Forged Stainless | F304, F304L, F316, F316L | ASTM A182 | High pressure and high temperature trims |

| Alloy Steels | WC6, WC9 | ASTM A217 | High temperature triple offset service |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater, RO plants, offshore |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / ASTM A351 | Desalination and chloride rich service |

| Nickel Alloys | Monel 400, Inconel 625, Inconel 718 | ASTM B564 | Sour gas, aggressive media |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Oxidizing and halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid and chemical duty |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and seawater systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702, Zr R60705 | ASTM B348 / ASTM B493 | Chlorides, seawater, specialty acids |

Industries Served

- Oil and Gas — tank farms, loading lines, utilities

- Power Generation — cooling water, condensate return, balance of plant

- Water and Desalination — transmission mains, RO trains, intake and outfall lines

- Petrochemical — unit operations, utilities, offsites

- Marine and Offshore — seawater cooling, fire water, ballast

- Mining and Metals — slurry side streams and plant water

Special Features

- Visual position indicator and lockable lever or gear for safe isolation control

- Cartridge style seats for quick replacement without removing the valve from the line

- Disc edge hard overlays to protect sealing surfaces in erosive service

- Seat choices in PTFE, UHMWPE, or elastomers for media compatibility beyond metal seats

- Stem extensions, chain wheel operators, and quarter turn gearboxes for difficult access points

- Internal coating options such as fusion bonded epoxy or ceramic filled epoxy for seawater and slurry services

Showing all 6 results