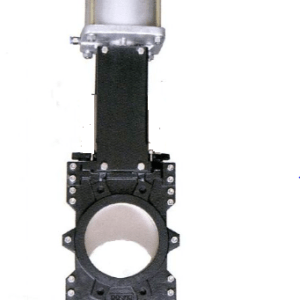

Knife Gate Valve

As a Knife Gate Valve Supplier in Dubai, UAE Valves delivers wafer, lug, flanged, and through-conduit knife gate valves engineered for slurry, pulp, wastewater, and utility service. A thin, sharpened gate slides through the media to open or close the line, shearing through solids and providing dependable shutoff in challenging duties. This simple motion keeps seats clear, reduces sticking, and ensures reliable performance with straightforward maintenance.

How Knife Gate Valves Work

A knife gate valve isolates flow by moving a thin gate through the media to shear solids and seal against a seat. The gate slides between body guides and compresses a resilient or metal seat when closed. To maintain sealing performance in slurry and fibrous duties, scrapers and deflectors clear solids away from the sealing surfaces during operation.

- Unidirectional designs seal pressure from one side only, making them economical for general slurry isolation.

- Bidirectional designs incorporate dual seats or transverse seals, allowing shutoff against pressure from either direction.

- Actuation options include manual handwheels, gearboxes, pneumatic cylinders, hydraulic cylinders, or electric actuators, often with limit switches or feedback for integration with plant control systems.

This design provides positive shutoff in slurry, pulp, and abrasive services, while remaining compact and easy to maintain compared to other valve types.

Knife Gate Valve Benefits

- Positive shutoff on slurry, fibrous, or abrasive media with low operating force

- Straight-through flow path reduces pressure drop and plugging

- Compact face-to-face dimensions simplify retrofits

- Easy top-entry service with replaceable seats and gland packing

- Options to manage solids build-up and extend service life

Types of Knife Gate Valves

- Unidirectional Knife Gate Valve – seals in one direction, cost-effective for general slurry service

- Bidirectional Knife Gate Valve – dual seats for sealing in pulsing or reversing flow

- Flanged Knife Gate Valve – rigid flanged ends for alignment and large-diameter pipelines

- Slurry Knife Gate Valve – reinforced body with wear sleeves and purge ports for abrasive duties

- Through Conduit Knife Gate Valve – gate clears the bore completely for minimal pressure loss and clean passage

Industries Served

Our experience as a Knife Gate Valve Supplier in Dubai extends across diverse industries, including:

- Mining & Minerals – tailings, concentrate, thickener underflow

- Water & Wastewater – raw water intake, sludge, grit lines

- Desalination – brine, seawater intake, pretreatment slurries

- Pulp & Paper – stock lines, rejects, recycled fiber

- Power Generation – bottom ash handling, slurry disposal lines

- Petrochemical & Chemical – utilities and solids-laden side streams

Technical Specifications

- Size Range: DN 50 to DN 2000 (2 in to 80 in)

- Pressure Ratings: PN 10 to PN 25 typical; ASME Class 150 on selected designs

- Temperature Range: −20 °C to +260 °C depending on body, seat, and packing materials

- End Connections: wafer, lugged, and flanged RF drilled to ASME B16.5 / EN 1092-1

- Face-to-Face: MSS SP-81 or manufacturer standard

- Seat Options: metal, natural rubber, EPDM, NBR, polyurethane, UHMWPE

- Packing Options: braided graphite, graphite-based low-emission sets, elastomer-based seals for slurry duty

- Actuation: handwheel, gearbox, pneumatic cylinder, hydraulic cylinder, or electric actuator

- Mounting: ISO 5211 actuator interfaces; custom topworks available

Design Standards

- MSS SP-81 – stainless, bonnetless, wafer and flanged knife gate valves

- ASME B16.5 / EN 1092-1 – flange standards

- ASME B16.25 – butt weld ends where applicable

- ISO 5211 – actuator mounting interfaces

- ISO 5208 / EN 12266 – pressure and seat leakage testing

- NACE MR0175 / ISO 15156 – materials for sour service

Inspection and Testing

- Hydrostatic shell and seat leakage tests to ISO 5208 / EN 12266

- Functional stroke and torque verification with travel stops set

- Packing leak checks with recorded gland settings

- Coating inspection and holiday testing for corrosive or buried service

- Positive Material Identification (PMI) for critical wetted parts

- Full traceability: EN 10204 3.1 / 3.2 certification packages, MTCs, and ITPs

- Third-party inspection available on request

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Ductile Iron | EN-GJS-450-10 | EN 1563 | Water, wastewater, non-corrosive slurries |

| Cast Carbon Steel | WCB, WCC | ASTM A216 | Industrial slurries and utility lines |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, brackish and RO water |

| Forged Stainless Steel | F304/L, F316/L | ASTM A182 | Gates, stems, high-stress parts |

| Duplex & Super Duplex | F51 (2205), F55 (2507) | ASTM A182 / A890 | Seawater, chloride-rich duties |

| Super Austenitic | F44 (254SMO) | ASTM A182 / A351 | High-chloride and desalination duties |

| Nickel Alloys | Monel 400, Inconel 625 | ASTM B564 | Sour service, aggressive chemical media |

| Bronze / Aluminium Bronze | C83600, C95800 | ASTM B148 | Marine service and splash zones |

Special Features

- Gate scrapers and deflector cones keep solids away from the sealing area

- Purge and flush ports at seat and packing zones to prevent build-up

- Replaceable wear sleeves and hardened gate edges for abrasive media

- Bonneted designs for zero external emissions where required

- Live-loaded packing with leak detection ports for monitoring

- Stem extensions and enclosed yokes for buried or remote chambers

- Customisation available for body materials, seat designs, and actuation methods to suit specific slurry, pulp, or wastewater conditions

Showing all 5 results