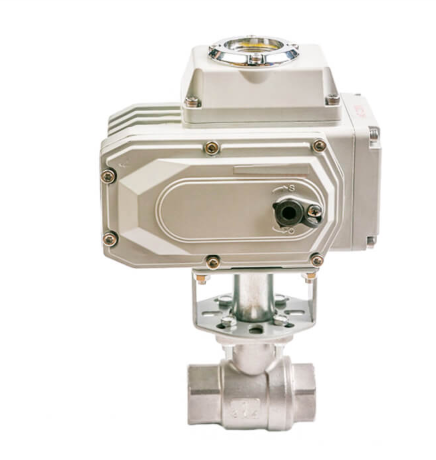

Electric Actuated Valve

Electric Actuated Valve Supplier in Dubai, UAE Valves delivers motorized valve packages that ensure reliable isolation and precise control in process networks where plant air is limited or unavailable. An electric actuator applies controlled torque and speed to the valve stem, enabling repeatable on/off duty, quiet operation, and smooth integration into plant automation. We supply complete electric actuated ball, butterfly, gate, globe, knife gate, and plug valves for new projects and upgrades across the Middle East.

How Electric Actuated Valves Work

A compact motor drives a gear train to rotate or lift the valve stem. Limit switches define open and closed positions, while torque switches prevent overload. For control duty, an electronic module interprets a 4–20 mA or 0–10 V signal and positions the valve with feedback to the DCS or PLC. Local selectors allow open, stop, and close from the field. Fail last, fail in place, or battery backed fail open or fail close options provide a defined safe state. Enclosures are sealed against dust and water, with ATEX or IECEx certification available for hazardous areas.

Benefits of Electric Actuated Valves

- Accurate positioning and steady control without plant air

- Simple integration with DCS or PLC using analog or digital signals

- Non intrusive setup and local controls for quick commissioning

- Lower maintenance than pneumatic systems in many services

- Quiet operation with power used only during movement

- Reduced lifecycle costs with fewer auxiliary systems

Types of Electric Actuated Valves

- Electric Actuated Ball Valve — quarter turn isolation with full bore options

- Electric Actuated Butterfly Valve — compact, lightweight solution for large diameters

- Electric Actuated Gate Valve — multi turn actuators for positive shutoff

- Electric Actuated Globe Valve — accurate positioning for throttling control

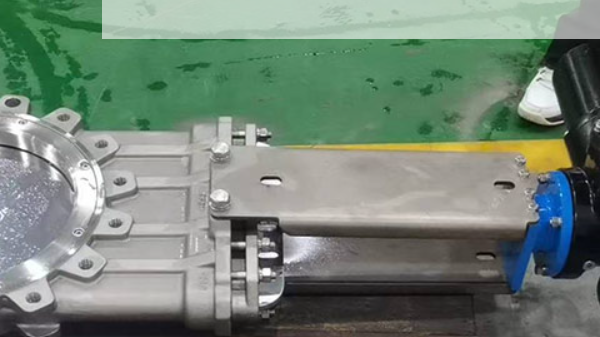

- Electric Actuated Knife Gate Valve — high thrust for slurry and pulp duties

- Electric Actuated Plug Valve — robust quarter turn for dirty or viscous media

Technical Specifications

- Valve size range: DN 15–DN 1200 (½″–48″)

- Pressure ratings: PN 10–PN 250; ASME Class 150–2500

- Temperature range: −196 °C to +600 °C depending on materials and coatings

- End connections: flanged RF/RTJ, butt weld, socket weld, threaded (small sizes), hubs on request

- Bore options: full bore and reduced bore available

- Actuator torque/thrust: 50–40,000 N·m typical; higher ranges on request

- Travel speed: 5–120 seconds per 90°; multi turn matched to duty and valve size

- Supply voltages: 24 VDC, 110–240 VAC single phase, 380–480 VAC three phase

- Control modes: on/off, inching, or modulating (4–20 mA / 0–10 V); Modbus, Profibus, and other protocols available

- Enclosures: IP67/IP68, NEMA 4/4X; ATEX and IECEx options for hazardous areas

- Duty cycle: S2 and S4 classes depending on model and service

Design Standards

- EN 15714–2 for electric actuators on industrial valves

- ISO 5211 and ISO 5210 for actuator to valve mounting

- IEC 60529 for enclosure protection ratings

- ATEX 2014/34/EU and IECEx for hazardous area compliance

- IEC 61508 for SIL capability on safety related applications

- Valve bodies to relevant standards (API 6D, EN 593, BS 1873, etc.)

Inspection and Testing

- Functional stroke testing with calibrated torque and travel checks

- Limit and torque switch settings documented with as built data

- Electrical checks including insulation resistance and high potential tests

- Communication testing for Modbus, Profibus, or other specified protocols

- Valve hydrostatic and leakage tests to API 598 or ISO 5208 when supplied assembled

- Factory acceptance tests with client witness available on request

- Full certification with serialized reports and EN 10204 3.1 / 3.2 material traceability

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Cast Carbon Steel | WCB, WCC | ASTM A216 | Hydrocarbons, steam |

| Low Temp Carbon Steel | LCB, LCC | ASTM A352 | Chilled or cryogenic service |

| Cast Stainless Steel | CF8, CF8M, CF3M | ASTM A351 | Corrosive fluids, water |

| Forged Stainless Steel | F304/L, F316/L | ASTM A182 | Trims, stems, high pressure |

| Duplex / Super Duplex | F51, F53, F55 (2507) | ASTM A182 / A890 | Seawater, RO, offshore |

| Super Austenitic | F44 (254SMO) | ASTM A182 / A351 | Desalination, high chloride |

| Nickel Alloys | Monel 400, Inconel 625/718 | ASTM B564 | Sour gas, aggressive service |

| Hastelloy | C276, B3 | ASTM B574 / B564 | Oxidizing/halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid duty |

| Bronze / Al Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and seawater systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702/705 | ASTM B348 / B493 | Chlorides, acids, seawater |

Industries Served

- Oil and Gas: manifolds, utilities, ESD and SDV applications

- Power Generation: fuel gas, cooling water, condensate systems

- Water and Desalination: RO trains, headers, intake and distribution lines

- Petrochemical and Chemical: unit isolation, batch control, utilities

- District Cooling: chilled water production and distribution

- Marine and Offshore: topsides, firewater, seawater cooling

As an Electric Actuated Valve Supplier in Dubai, UAE Valves configures packages to meet local service conditions, approval requirements, and documentation standards. Our solutions are installed across desalination plants, district cooling networks, and refinery shutdown systems throughout the Middle East.

Special Features

- Local control station with position indication and diagnostics

- Non intrusive setup; parameter changes without opening the enclosure

- Data logging of torque and position for preventive maintenance

- Bluetooth or NFC options for quick commissioning

- Battery backed fail safe return for defined safe states

- Redundant limit and torque sensing for high integrity applications

- Space heaters to prevent condensation and extend electronics life

- Manual declutch and handwheel for safe local operation

- Partial stroke test routines for SIL 2/3 service valves

Customization available for voltage, control signal, torque range, travel speed, fail position, enclosure rating, and coatings.

Showing all 18 results