Control Valve

UAE Valves is a trusted Control Valve Supplier in Dubai, delivering engineered solutions for accurate flow, pressure, and temperature regulation across critical industries. Our control valves are designed to ensure smooth modulation and tight shutoff, helping facilities in oil and gas, power, water treatment, and refining achieve safe, reliable, and efficient operations.

How Control Valve Work

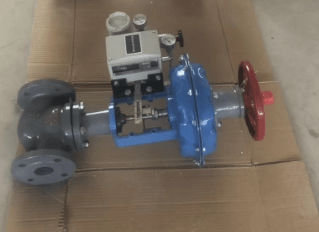

A control valve works as the regulator in an automated loop. Guided by a controller, the actuator moves internal trim such as a plug, ball, or disc to adjust the flow area inside the valve body. This ensures the system delivers the right amount of fluid at the right time, reducing pressure swings, improving energy use, and supporting consistent plant performance.

Control Valve Benefits

- Precise and repeatable flow control for stable operations.

- Durable materials and coatings to withstand corrosion and wear.

- Smooth actuation with low operating torque for efficient automation.

- Trim designs that reduce noise and mitigate cavitation.

- Seamless integration with plant instrumentation and control systems.

Types of Control Valves

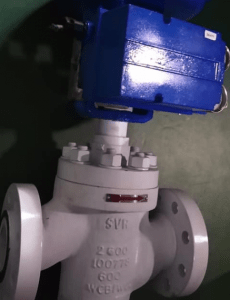

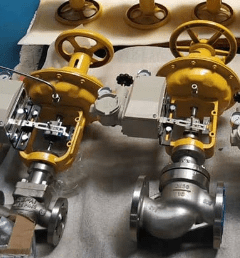

- Electric Actuated Control Valve – suited for advanced automation with electronic actuation and remote monitoring.

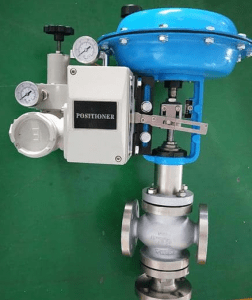

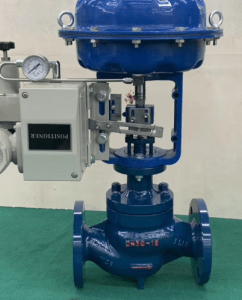

- Pneumatic Control Valve – ideal for fast response, high cycling, and air-driven fail-safe applications.

Industries Served

- Oil and Gas – refineries, offshore platforms, and pipelines.

- Power Generation – steam, condensate, and feedwater control.

- Water and Wastewater – distribution, treatment, and pressure regulation.

- Desalination – intake systems, pretreatment, and RO processes.

- Marine and Offshore – ballast, seawater cooling, and utility loops.

- Chemical and Petrochemical – clean and corrosive media handling.

- Mining and Minerals – slurry handling and utility streams.

- Pulp and Paper – process chemicals and utility flow regulation.

Material Selection for Control Valves

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Steam, hydrocarbons, low-temperature service |

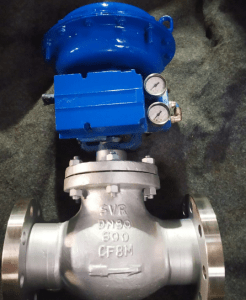

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, oxygen, nitrogen |

| Forged Stainless | F304, F316, F316L | ASTM A182 | High-pressure applications |

| Alloy Steels | WC6, WC9 | ASTM A217 | High-temperature steam service |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater, offshore, chloride-rich service |

| Nickel Alloys | Monel 400, Inconel 625 | ASTM B564 | Hydrogen, helium, corrosive gases |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Aggressive acids and chemicals |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid service |

| Bronze / Aluminium Bronze | C95400, C95800 | ASTM B148 | Marine and seawater |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702, R60705 | ASTM B348 / ASTM B493 | Seawater, chlorides, specialty acids |

Technical Specifications

- Design standards: ASME B16.34, IEC 60534, API 6D/608, EN 593, ISO 5208

- Size range: DN15–DN1200 (½″–48″)

- Pressure ratings: ASME Class 150–1500; PN10–PN160

- End connections: flanged (RF/RTJ), butt-weld, socket-weld, wafer/lug

- Leakage class: ANSI/FCI 70-2 (IV–VI); ISO 5208 Rate A

- Temperature range: −196 °C to +600 °C (material dependent)

- Control characteristics: equal-percentage, linear, quick-open

Inspection and Testing

- Hydrostatic and pneumatic testing performed in-house

- API 598 pressure and leakage verification

- ANSI/FCI 70-2 seat leakage classification

- Fire-safe testing to API 607 available on request

- Cryogenic testing to BS 6364 / MSS SP-134 if specified

- Supplied with ISO 9001 certification and full material traceability

Special Features

- Extended bonnets for cryogenic or high-temperature services

- Smart positioners with HART, Profibus, or Fieldbus protocols

- SIL-capable actuation and partial-stroke testing options

- Low-emission packing for environmental compliance

- Custom trims, alloys, and actuation packages to match the service

Showing all 15 results