Check Valve

Across Dubai’s oil, water, and power networks, UAE Valves is a Check Valve Supplier in Dubai delivering non return valves that protect pumps, prevent reverse flow, and help stabilize pipelines against water hammer. We support EPCs and plant teams with application sizing, documentation packs, and materials that match local seawater and process conditions.

How Check Valves Work

A check valve allows flow in one direction and closes automatically when the flow reverses. Forward differential pressure lifts a disc, plates, piston, or ball off the seat; when velocity drops or reverses, the closure element returns to the seat. Correct spring selection and streamlined internals reduce slam, shorten closure time, and limit pressure spikes.

Check Valve Benefits

- Protects pumps, compressors, and meters from reverse flow

- Minimizes water hammer and pressure surges during starts and trips

- Low pressure drop options to cut energy loss in continuous service

- Automatic operation with no external power or control signals

- Broad materials and end connections for fast project integration

Types of Check Valves

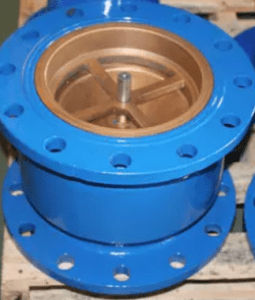

- Dual Plate Check Valve: compact wafer body with two spring loaded plates for quick closure and low loss

- Single Plate Check Valve: slim wafer single disc for tight spaces and general service

- Lift Check Valve: vertical piston or ball lift for high pressure clean media

- Non Slam Swing Check Valve: spring assisted swing disc to reduce slam on deceleration

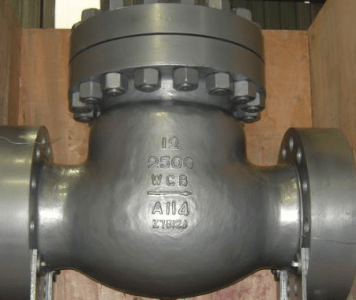

- Pressure Seal Check Valve: pressure energized bonnet seal for high temperature and high pressure

- Tilting Disc Check Valve: short travel disc for fast closure and lower head loss in large lines

- Swing Check Valve: full bore swing disc for low velocities and lines with solids

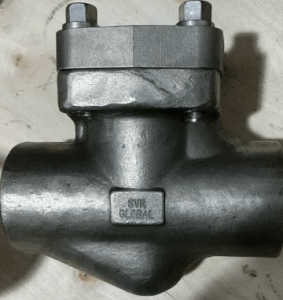

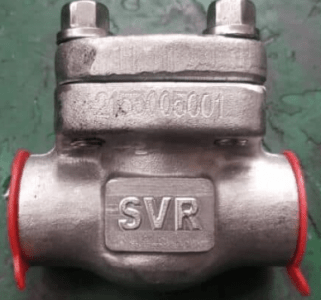

- Forged Steel Check Valve: compact threaded or socket weld ends for utilities and block in points

Design Standards

- API 594 for wafer, wafer lug, and double flanged check valves

- ASME B16.34 for design and pressure and temperature ratings

- API 6D for pipeline service where specified

- EN 12334 for industrial check valves; ISO 5208 for pressure testing

Inspection and Testing

- API 598 visual, shell, and seat leakage testing

- MSS SP 61 hydrostatic and pneumatic tests

- Cracking pressure verification and dynamic closure time testing to assess slam potential

As a manufacturer, we log test data for each assembly and issue traceable certificates.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Hydrocarbons, steam, general service |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, oxygen clean services |

| Forged Stainless | F304, F304L, F316, F316L | ASTM A182 | High pressure utility and process lines |

| Alloy Steels | WC6, WC9 | ASTM A217 | High temperature steam service |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater, RO, offshore environments |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / ASTM A351 | Desalination and chloride rich seawater service |

| Nickel Alloys | Monel 400, Inconel 625, Inconel 718 | ASTM B564 | Sour gas, high temperature, aggressive media |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Oxidizing or halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid and chemical duty |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and brackish water systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702, R60705 | ASTM B348 / ASTM B493 | Chlorides, seawater, specialty acids |

Industries Served

- Oil and Gas: gathering, transmission, refinery utilities

- Power Generation: condensate, boiler feed auxiliaries, cooling water

- Water and Desalination: distribution, RO trains, intake and outfall lines

- Petrochemical: unit operations, flare headers, utility manifolds

- Marine and Offshore: fire water, ballast, seawater cooling

- Mining and Metals: slurry side streams, plant water, air

As a Check Valve Supplier in Dubai, we support existing facilities and new builds across the Middle East. Available as industrial check valves for Dubai projects, and supplied region wide as a non return valves supplier in the UAE.

Special Features

- Retainerless dual plate designs to eliminate body penetrations and potential leak paths

- Tuned springs and hinges to match cracking pressure and closure speed to your system profile

- Dashpot and damping options on large swing or tilting disc valves to reduce slam

- Full bore pipeline designs compatible with pigging where specified

- NACE MR0175 compliant materials for sour service on request

Customization available for face to face, end connections, seat materials, and spring ranges to match project specifications.

Showing all 10 results