Gate valves play a central role in isolation and flow control across oil & gas, water networks, chemical plants, district cooling systems, and energy facilities. For plant designers, maintenance staff, and engineers operating in industrial infrastructure where clear operation, process efficiency, and precise mechanical motion are vital, they must know the distinction between rising stem and non-rising stem gate valves. This handbook explains the key differences between rising stem and non-rising stem gate valves, offering practical guidance for selecting the right option across industries where UAE valves are commonly used. Supported by realistic field judgments and application circumstances, it also helps pinpoint the best place for each valve.

Understanding Gate Valve Stem Mechanisms

Gate valves operate using a linear motion to raise or lower a wedge (gate) to either permit or halt flow. Rising stem arrangements differ from non-rising stem configurations in how the stem engages with the gate and in the way motion is outwardly shown.

Though they influence access, visual indication, and installation requirements, both share the same basic aim: full-bore flow with minimal pressure loss.

What Is the Difference Between Rising Stem and Non-Rising Stem Gate Valves?

| Rising Stem Gate Valves | Non-Rising Stem Gate Valves |

| The stem moves upward as the valve opens. | The stem rotates but does not move vertically. |

| The rotation converts into linear motion using a stem nut fixed inside the bonnet. | The stem threads engage directly with the gate, causing vertical movement internally. |

| Stem position is externally visible, making it easier to check valve status. | Ideal for limited-space environments or underground installations. |

| Requires vertical clearance. | Stem position is not externally visible without an indicator. |

Design and Operational Distinctions

Design Features of Rising Stem Valves

- External stem thread exposure

- Clear indication of open or closed status

- Larger yoke and bonnet assembly

- Typically used in above-ground setups

Design Features of Non-Rising Stem Valves

- Internal stem thread engagement

- More compact body and bonnet

- Better suited for buried or confined installations

- Often used with position indicators for visibility

Operational Differences

- Rising stem valves provide straightforward visual confirmation.

- Non-rising stem valves require less space but can accumulate debris in the bonnet.

- Rising stem designs reduce thread wear as they operate externally, whereas internal threads in non-rising stem designs engage directly with the fluid medium.

Stem Movement Behavior

Gate valve stem movement governs how the wedge travels:

Rising Stem Mechanism

- When the handwheel turns, the stem nut drives the stem upward.

- The gate moves through a guided vertical path, minimizing internal friction.

- Because the stem is external, operators observe movement in real time.

Non-Rising Stem Mechanism

- The handwheel rotates the stem, which threads into the gate.

- The gate rises or lowers while the stem remains stationary.

- Less vertical clearance is needed, making it suitable for urban, subterranean, and compact industrial piping.

This section helps engineers visualize internal and external motion differences.

Flow Characteristics and Mechanism

The core flow characteristics remain similar, but stem type can influence maintenance or usage preferences.

Flow Qualities:

- Gate valves offer full-bore flow, reducing turbulence.

- Pressure drop is minimal when fully open.

- Used for isolation rather than regulation.

Mechanism Influence:

- Stem configuration does not change flow, but it affects ease of actuation and mechanical wear.

- Internal-stem systems in non-rising valves may see more friction depending on media type.

Comparison: Rising Stem vs Non-Rising Stem Gate Valves

| Feature | Rising Stem | Non-Rising Stem |

| Stem Movement | Moves upward | Rotates only |

| Visibility | High | Requires indication |

| Space Requirement | Needs vertical space | Compact |

| Wear Exposure | External threads | Internal threads |

| Suitability | Above ground | Buried or confined |

| Maintenance Access | Easier | Slightly complex |

| Media Interaction | No thread contact | Threads exposed to media |

When Should You Choose a Rising Stem Gate Valve?

Choose rising stem valves when:

- Visual confirmation of valve status is essential

- The installation is above ground

- There is sufficient vertical room

- The application includes frequent inspections

- Lower thread wear is preferred

- The line contains abrasive or particulate media

- Industry standards require visible stem indicators (common in fire protection and refinery applications)

Rising stem valves are favored in facilities where operational clarity is a priority.

When Should You Choose a Non-Rising Stem Gate Valve?

Choose non-rising stem valves when:

- Space is restricted, such as underground chambers or narrow plants

- The valve must fit within a compact assembly

- The system requires a flush bonnet and reduced external hardware

- Housing, district cooling, stormwater, or irrigation networks use buried valves

- Weight and external profile must remain minimal

- Additional position indicators can be installed

Non-rising stem designs allow flexibility where structural constraints exist.

Industrial Applications

Both types are used across various sectors depending on installation and space availability:

- Oil and Gas

- Water Treatment and Distribution

- Desalination Plants

- Petrochemical and Refineries

- District Cooling Networks

- Fire Protection Systems

- Marine & Offshore

- Power Generation

What Factors Should Engineers Consider When Selecting Rising vs Non-Rising Stem Valves?

Engineers typically evaluate:

- Available installation space

- Visibility needs for open/close indication

- Maintenance access

- Media characteristics (abrasive or clean)

- Frequency of operation

- Corrosion exposure

- Required standards compliance

- Long-term operating posture

This helps determine which stem configuration aligns best with operational needs.

Technical Data and Specifications

| Parameter | Rising Stem | Non-Rising Stem |

| Nominal Size Range | 2″–48″ | 2″–60″ |

| Pressure Class | ANSI Class 150–2500 | ANSI Class 150–2500 |

| Design Standards | API 600, API 6D, ASME B16.34 | API 600, API 6D, ASME B16.34 |

| Face-to-Face Standards | ASME B16.10 | ASME B16.10 |

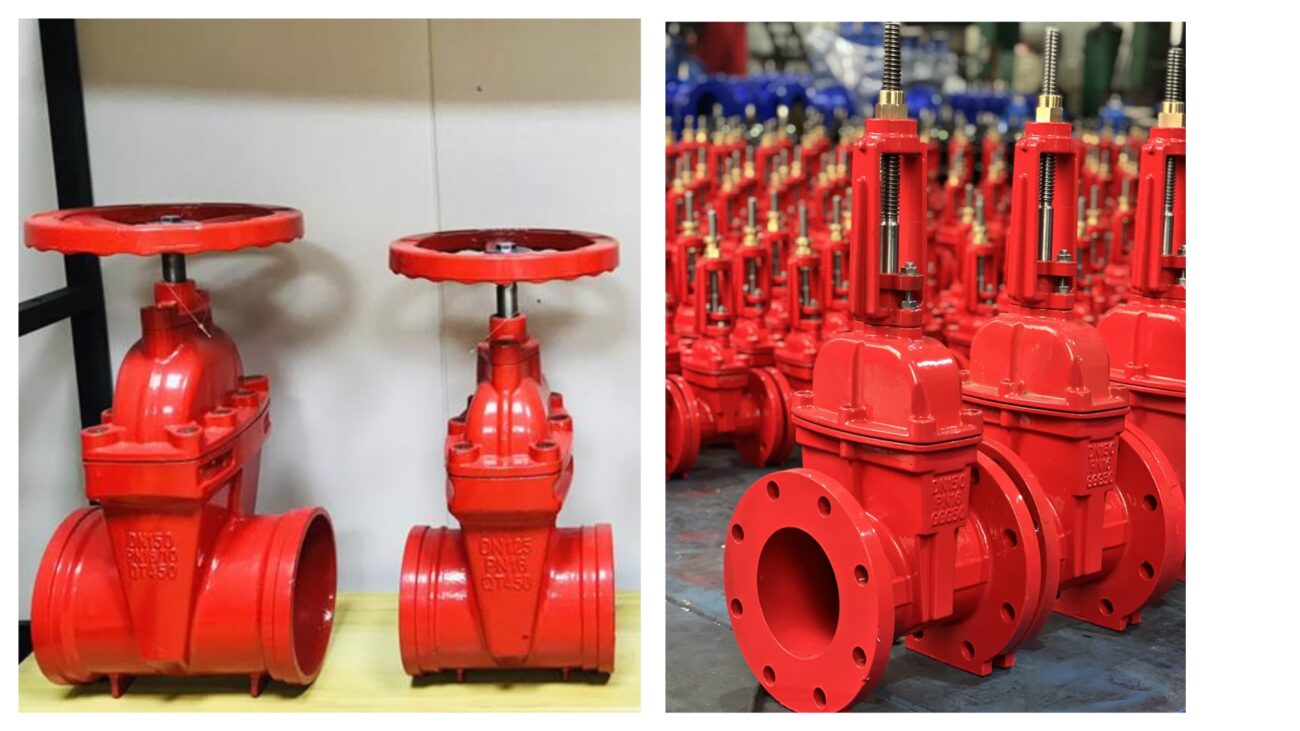

| End Connections | Flanged, RF, RTJ, BW | Flanged, BW, Grooved |

| Stem Type | Rising external thread | Internally threaded |

| Body Materials | Carbon steel, stainless steel, alloy steel, ductile iron | Same range |

| Testing Standards | API 598, ISO 5208 | API 598, ISO 5208 |

| Temperature Range | –29°C to 425°C (material dependent) | –29°C to 425°C |

| Coatings | Fusion bonded epoxy, zinc coating, PTFE lining | Same options |

| Applications | Above-ground isolation | Buried or compact spaces |

Industrial Standards and Testing Requirements

Both gate valve types must comply with:

- API 600 / API 6D for steel gate valve design

- ASME B16.34 for pressure-temperature parameters

- ASME B16.10 for face-to-face dimensions

- API 598 or ISO 5208 for pressure testing

- NACE MR0175 / ISO 15156 when used in sour service

- Fire-safe testing standards like API 607 (based on application)

Standards ensure valve performance across pressure, temperature, and environmental ranges.

The demands for visibility, space availability, installation constraints, access for maintenance, and the specific industrial environment will help to guide the selection between non-rising stem gate valves and rising stem ones. Either design offers dependable performance in stand-alone chores if precisely fitted to system requirements. Meeting requirements like API 6D, API 600, ASME B16.34, and API 598 ensures the valve satisfies the needed industrial use operating and testing requirements.

By means of a careful analysis of mechanics, room conditions, and flow behavior, engineers may pick the optimum gate valve design for long-term, efficient use in many industries.